Hot Online

400-027-6688

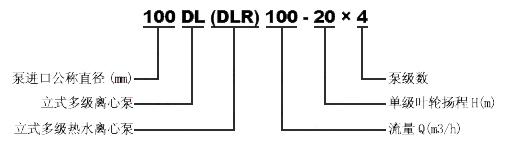

Model significance

Product profile

DL, DLR series vertical multistage centrifugal pump (low speed n=1450r/min) is the factory according to the water supply market of high-rise building's actual needs and the National Fire Protection Agency GB 6245-1998 "fire pump performance requirements and test methods" standard of research and development is a new type of new products. Use of a medium that does not contain hard particles and physical and chemical properties similar to water. Flow range is 5 ~ 360m3/h, the lift range is 22 ~ 300m, matching the power range is 1.5 ~ 220KW, the scope for phi 40 Phi 200m. The same pump outlet can be set to 1 ~ 5 exports.

Product features

The hydraulic model of excellent domestic energy efficient DL vertical multistage centrifugal pump, has the advantages of high efficiency, the performance of flat curve, wide operating range, comply with the relevant provisions of the fire department, to meet different user needs; DL vertical multistage centrifugal pump with vertical sectional structure, and the advantages of stable operation, low noise, long service life, covering small area, convenient installation and maintenance etc..

Product use

Mainly used in high-rise building water supply, fire sprinkler water, constant pressure water supply, automatic water curtain and water supply, but also can be applied to the mine drainage, long distance water supply, supporting the use of various equipment and various production process water. DL vertical multistage centrifugal pump medium temperature is not more than 80 DEG C, DLR medium temperature of not more than 120

Use conditions

1, the use of the media should be similar to water, kinematic viscosity <150mm2/s, and no hard particles, non corrosive nature;

2, DL vertical multistage centrifugal pump using the environment altitude of <1000 meters, more than should be put in order, so that the factory to provide you with more reliable products;

3, medium temperature -15 C ~ 120 c;

4, the maximum working pressure is less than 2.5MPa;

5, the ambient temperature should be lower than 40 degrees, relative humidity is less than 95%.

Structure description

DL vertical multistage centrifugal pump is composed of two parts: motor and pump, the motor is Y type three-phase asynchronous motor, the pump and motor are connected by coupling, and the whole is rigid connection. The pump consists of a stator and a rotor. The stator part of the pump is composed of the inlet section, the middle section, the guide vane, the outlet section and the stuffing box. In order to prevent the wear of the stator, the stator is provided with a sealing ring, a balance sleeve, etc.. The rotor consists of a shaft, impeller, balance hub etc.. The rotor is arranged at the lower end of the water lubricated bearing, the upper part of angular contact ball bearing, the axial force of DL vertical multistage centrifugal pump by most of the balance drum to bear, the remaining small part of residual axial force angular contact ball bearings to bear. The water inlet section, the water outlet section and the joint surface paper pad are sealed through the connection. Seal with packing or mechanical seal, the user can choose according to need.

DL vertical multistage centrifugal pump in the direction of rotation from the drive end to the counter clockwise rotation.

1, DL vertical multistage centrifugal pump compact structure, small size, beautiful appearance, small footprint, saving construction costs;

Inlet and outlet 2, DL vertical multistage centrifugal pump in the same center line, simplify the connection pipeline;

3, according to the actual situation, DL vertical multistage centrifugal pump import and export can be assembled into 90 degrees, 180 degrees, 270 degrees in different directions;

4, according to the actual situation, DL vertical multistage centrifugal pump exports can be assembled into 1~5 exports, to meet the same pump to obtain different lift;

| 序号 | 名称 | 材料或型号 | 序号 | 名称 | 材料或型号 |

| 1 | 电机 | Y系列(V5)4极 | 12 | 出水段 | HT200 |

| 2 | 联轴器 | HT200 | 13 | 平衡套 | HT200 |

| 3 | 弹性块 | 橡 胶 | 14 | 平衡鼓 | HT200 |

| 4 | 轴承压盖 | HT200 | 15 | 末级导叶 | HT200 |

| 5 | 轴承并帽 | 45 | 16 | 中段 | HT200 |

| 6 | 轴承盒 | HT200 | 17 | 导叶 | HT200 |

| 7 | 轴承 | 180系列 | 18 | 叶轮 | HT200 |

| 8 | 挡水套 | 45 | 19 | 出水段 | HT200 |

| 9 | 石棉压盖 | HT200 | 20 | 下轴套 | 45 |

| 10 | 石棉 | 石 棉 | 21 | 下轴承 | 铜合金 |

| 11 | 填料函体 | HT200 | 22 | 轴 | 45、2Cr13 |

| 注:1、该泵型可按客户需要定做成热水型; | |||||

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

40DL6.2-11.2*2 | 2 | 1450 | 40 | 3.19 | 6.2 | 23.6 | 1.5 | 152 |

40DL6.2-11.2*3 | 3 | 1450 | 40 | 3.19 | 6.2 | 35.4 | 2.2 | 169 |

40DL6.2-11.2*4 | 4 | 1450 | 40 | 3.19 | 6.2 | 47.2 | 3 | 186 |

40DL6.2-11.2*5 | 5 | 1450 | 40 | 3.19 | 6.2 | 59 | 4 | 203 |

40DL6.2-11.2*6 | 6 | 1450 | 40 | 3.19 | 6.2 | 70.8 | 4 | 220 |

40DL6.2-11.2*7 | 7 | 1450 | 40 | 3.19 | 6.2 | 82.6 | 5.5 | 237 |

40DL6.2-11.2*8 | 8 | 1450 | 40 | 3.19 | 6.2 | 94.4 | 5.5 | 254 |

40DL6.2-11.2*9 | 9 | 1450 | 40 | 3.19 | 6.2 | 106.2 | 7.5 | 271 |

40DL6.2-11.2*10 | 10 | 1450 | 40 | 3.19 | 6.2 | 118 | 7.5 | / |

40DL6.2-11.2*11 | 11 | 1450 | 40 | 3.19 | 6.2 | 129.8 | 7.5 | / |

40DL6.2-11.2*12 | 12 | 1450 | 40 | 3.19 | 6.2 | 141.6 | 11 | / |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

50DL12.6-12.2*2 | 2 | 1450 | 54 | 2.66 | 12.6 | 24.4 | 3 | 15.3 |

50DL12.6-12.2*3 | 3 | 1450 | 54 | 2.66 | 12.6 | 36.6 | 3 | 18 |

50DL12.6-12.2*4 | 4 | 1450 | 54 | 2.66 | 12.6 | 48.8 | 4 | 23.1 |

50DL12.6-12.2*5 | 5 | 1450 | 54 | 2.66 | 12.6 | 61 | 5.5 | 33 |

50DL12.6-12.2*6 | 6 | 1450 | 54 | 2.66 | 12.6 | 73.2 | 5.5 | 24 |

50DL12.6-12.2*7 | 7 | 1450 | 54 | 2.66 | 12.6 | 85.4 | 7.5 | 15 |

50DL12.6-12.2*8 | 8 | 1450 | 54 | 2.66 | 12.6 | 97.6 | 7.5 | 18 |

50DL12.6-12.2*9 | 9 | 1450 | 54 | 2.66 | 12.6 | 109.8 | 11 | 22 |

50DL12.6-12.2*10 | 10 | 1450 | 54 | 2.66 | 12.6 | 122 | 11 | / |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

65DL30-16*2 | 2 | 1450 | 62 | 2.82 | 30 | 32 | 5.5 | 349 |

65DL30-16*3 | 3 | 1450 | 62 | 2.82 | 30 | 48 | 7.5 | 390 |

65DL30-16*4 | 4 | 1450 | 62 | 2.82 | 30 | 64 | 11 | 460 |

65DL30-16*5 | 5 | 1450 | 62 | 2.82 | 30 | 80 | 15 | 509 |

65DL30-16*6 | 6 | 1450 | 62 | 2.82 | 30 | 96 | 15 | 537 |

65DL30-16*7 | 7 | 1450 | 62 | 2.82 | 30 | 112 | 18.5 | 603 |

65DL30-16*8 | 8 | 1450 | 62 | 2.82 | 30 | 128 | 22 | 639 |

65DL30-16*9 | 9 | 1450 | 62 | 2.82 | 30 | 144 | 22 | 667 |

65DL30-16*10 | 10 | 1450 | 62 | 2.82 | 30 | 160 | 30 | 720 |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

80DL50-20*2 | 2 | 1450 | 70 | 2.5 | 50 | 40 | 11 | 461 |

80DL50-20*3 | 3 | 1450 | 70 | 2.5 | 50 | 60 | 15 | 522 |

80DL50-20*4 | 4 | 1450 | 70 | 2.5 | 50 | 80 | 22 | 608 |

80DL50-20*5 | 5 | 1450 | 70 | 2.5 | 50 | 100 | 30 | 728 |

80DL50-20*6 | 6 | 1450 | 70 | 2.5 | 50 | 120 | 30 | 768 |

80DL50-20*7 | 7 | 1450 | 70 | 2.5 | 50 | 140 | 37 | 822 |

80DL50-20*8 | 8 | 1450 | 70 | 2.5 | 50 | 160 | 45 | 898 |

80DL50-20*9 | 9 | 1450 | 70 | 2.5 | 50 | 180 | 45 | 938 |

80DL50-20*10 | 10 | 1450 | 70 | 2.5 | 50 | 200 | 55 | / |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

100DL72-20*2 | 2 | 1450 | 72 | 2.8 | 72 | 40 | 15 | 521 |

100DL72-20*3 | 3 | 1450 | 72 | 2.8 | 72 | 60 | 18.5 | 599 |

100DL72-20*4 | 4 | 1450 | 72 | 2.8 | 72 | 80 | 30 | 727 |

100DL72-20*5 | 5 | 1450 | 72 | 2.8 | 72 | 100 | 37 | 781 |

100DL72-20*6 | 6 | 1450 | 72 | 2.8 | 72 | 120 | 37 | 821 |

100DL72-20*7 | 7 | 1450 | 72 | 2.8 | 72 | 140 | 45 | 897 |

100DL72-20*8 | 8 | 1450 | 72 | 2.8 | 72 | 160 | 55 | 1044 |

100DL72-20*9 | 9 | 1450 | 72 | 2.8 | 72 | 180 | 55 | 1084 |

100DL72-20*10 | 10 | 1450 | 72 | 2.8 | 72 | 200 | 75 | / |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

100DL100-20*2 | 2 | 1450 | 72 | 3.5 | 100 | 40 | 18.5 | 554 |

100DL100-20*3 | 3 | 1450 | 72 | 3.5 | 100 | 60 | 30 | 687 |

100DL100-20*4 | 4 | 1450 | 72 | 3.5 | 100 | 80 | 37 | 746 |

100DL100-20*5 | 5 | 1450 | 72 | 3.5 | 100 | 100 | 45 | 827 |

100DL100-20*6 | 6 | 1450 | 72 | 3.5 | 100 | 120 | 55 | 979 |

100DL100-20*7 | 7 | 1450 | 72 | 3.5 | 100 | 140 | 75 | 1159 |

100DL100-20*8 | 8 | 1450 | 72 | 3.5 | 100 | 160 | 75 | 1204 |

100DL100-20*9 | 9 | 1450 | 72 | 3.5 | 100 | 180 | 90 | 1354 |

100DL100-20*10 | 10 | 1450 | 72 | 3.5 | 100 | 200 | 90 | / |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

150DL150-20*2 | 2 | 1450 | 80 | 2.8 | 150 | 40 | 30 | 569 |

150DL150-20*3 | 3 | 1450 | 80 | 2.8 | 150 | 60 | 37 | 707 |

150DL150-20*4 | 4 | 1450 | 80 | 2.8 | 150 | 80 | 45 | 771 |

150DL150-20*5 | 5 | 1450 | 80 | 2.8 | 150 | 100 | 55 | 857 |

150DL150-20*6 | 6 | 1450 | 80 | 2.8 | 150 | 120 | 75 | 1060 |

150DL150-20*7 | 7 | 1450 | 80 | 2.8 | 150 | 140 | 75 | 1245 |

150DL150-20*8 | 8 | 1450 | 80 | 2.8 | 150 | 160 | 90 | 1295 |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

150DL160-25*2 | 2 | 1450 | 76 | 3.5 | 160 | 40 | 37 | 873 |

150DL160-25*3 | 3 | 1450 | 76 | 3.5 | 160 | 60 | 55 | 1086 |

150DL160-25*4 | 4 | 1450 | 76 | 3.5 | 160 | 80 | 75 | 1291 |

150DL160-25*5 | 5 | 1450 | 76 | 3.5 | 160 | 100 | 90 | 1466 |

150DL160-25*6 | 6 | 1450 | 76 | 3.5 | 160 | 120 | 110 | 1633 |

150DL160-25*7 | 7 | 1450 | 76 | 3.5 | 160 | 140 | 132 | 1803 |

150DL160-25*8 | 8 | 1450 | 76 | 3.5 | 160 | 160 | 132 | 1873 |

150DL160-25*9 | 9 | 1450 | 76 | 3.5 | 160 | 180 | 160 | 2003 |

Model | steps | speed | efficiency | Essential cavitation | flow | lift | power | weight |

r/min | % | M | m3/h | M | kw | Kg | ||

200DL300-20*2 | 2 | 1450 | 79 | 5 | 300 | 40 | 55 | 983 |

200DL300-20*3 | 3 | 1450 | 79 | 5 | 300 | 60 | 75 | 1196 |

200DL300-20*4 | 4 | 1450 | 79 | 5 | 300 | 80 | 110 | 1845 |

200DL300-20*5 | 5 | 1450 | 79 | 5 | 300 | 100 | 132 | 1975 |

200DL300-20*6 | 6 | 1450 | 79 | 5 | 300 | 120 | 160 | 2120 |

200DL288-30*2 | 2 | 1450 | 77.9 | 3.7 | 288 | 60 | 75 | / |

200DL288-30*3 | 3 | 1450 | 77.9 | 3.7 | 288 | 90 | 110 | / |

200DL288-30*4 | 4 | 1450 | 77.9 | 3.7 | 288 | 120 | 132 | / |

200DL288-30*5 | 5 | 1450 | 77.9 | 3.7 | 288 | 150 | 160 | / |

200DL288-30*6 | 6 | 1450 | 77.9 | 3.7 | 288 | 180 | 200 | / |